Our History

The Brinly-Hardy Company traces its origin to “Little John Brinly”, a blacksmith who set up shop in Simpsonville, Kentucky, around 1800 and made plows in his spare time when he wasn’t shoeing horses, mules and oxen of the settlers newly arrived in Kentucky or for those headed West. He crafted the “Brinly” plow with a wooden moldboard, cast iron front, point and heel bolt around 1805. This plow was once owned by Isaac Shelby, the first governor of Kentucky, and is now in the Kentucky Historical Museum in Frankfort, Kentucky.

The son of “Little John Brinly”, Mr. T. E. C. Brinly, later fashioned a one-piece steel plow from a saw blade around 1837. He is considered the first manufacturer of steel plows in this portion of the country. The excellence of these plows soon made them famous among the farmers of Kentucky. Still in Simpsonville, Mr. Brinly worked at the forge, turning out plows for the neighboring farmers.

Until 1859, Mr. T. E. C. Brinly was still manufacturing plows at Simpsonville. At that time he furnished nearly his entire output to W. B. Belknap & Company in Louisville, from whom he purchased his steel and other materials. Belknap bought the plows for shipment down river by steamboat or flatboat to Memphis, Natchez, Vicksburg and New Orleans. The plows quickly gained a good reputation in the South. The method employed in doing business in those days was for him to send in a wagon load of plows, and haul back a wagon load of steel. Sometimes he would walk the 20 miles back to Simpsonville, if the load was too heavy for his mules.

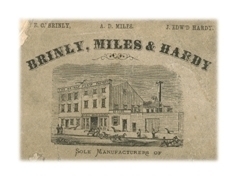

Mr. Morris Belknap of the firm of W. B. Belknap & Company, induced Mr. Brinly to come to Louisville to occupy a site located on Main Street between Brook and Floyd. In 1859, Mr. Brinly moved his plow factory to Louisville. Later, the plant was moved one block to Main Street between Preston and Floyd.

In the early days, the firm in Louisville had several partnerships. In 1863, Mr. James Edward Hardy joined the firm. And in 1900, the company name was incorporated as Brinly-Hardy Company. Mr. Brinly died in 1902 at the age of 80 and since that time, there haven’t been any Brinly’s involved in the company.

Mr. James Edward Hardy, Sr. became the president of Brinly-Hardy Company, and remained in that position until his death at age 88 in 1922. At that time, his son, William B. Hardy, who had joined the company in 1902, became President. Mr. William B. Hardy’s son, James E. Hardy, Jr. joined the company in 1919, and in 1920 became plant superintendent. In 1926, Mr. Hardy, Jr. was promoted to Sales Manager, Secretary, and Vice President, then at the death of William B. Hardy in 1930, became the third generation President of the company.

Mr. James E. Hardy, Jr. had two children (twins), James E., III and Lois Jean. After the death of Mr. Hardy Jr., James E. Hardy, III became president which represented four generations of family presidents. Mr. Hardy, III and his wife, Barbara have three children. Since 1994, their youngest daughter, Jane W. Hardy, has served as the fifth generation president, while her father remained as Chairman of the Board until his death in February, 2001.

Today, Brinly-Hardy Company is primarily a manufacturer of lawn and garden tractor accessories. The products are sold nation-wide through distributors, chain stores and home improvement centers. In addition to labeled products, the firm markets products through tractor manufacturers under their own private labels. Brinly-Hardy produces some 110 models of utility carts, lawn rollers, plows, disk harrows, cultivators, aerators, dethatchers, fertilizer spreaders and snow blades.

The building on the corner of Preston and Main Streets, 338-340 East, was built in 1865 as Eddy Drug Store. The building at 334 E. Main, which was connected to the corner structure at some point in time, wraps around the corner building and has a facade on Preston Street. This was built in 1884 for William Wacker, feather renovator. The building located at 324-32 E. Main Street is a complex of four structures, some dating as early as 1867. These are Brinly-Hardy’s original buildings, occupied by them from 1869-1999. Structures are typical of the 19th Century commercial structures that line East Main Street. Information obtained in part from a Kentucky Historic Resources Inventory report, dated March, 1984.

103 N. Preston. This structure is first listed in the 1902 Directory as the Big Four Freight Depot. In 1909, The Chesapeake and Ohio Rail Road Company took over the building and continued its use as a freight depot until 1964 when purchased by Brinly-Hardy Company. The building was used as Brinly-Hardy’s only warehouse and shipping area, and was vital to the operation of the business. The Romanesque revival, a style adapted from 8th to 12th Century church architecture, gave the old depot the look of a basilica, a cathedral of commerce and is an adaptation of the Richardsonian themes. Richardson was noted for his innovative and powerful designs for railroad stations.

Information obtained in part from “The Courier-Journal Magazine”, dated 12/6/87. NOTE: The railroad building was sold to the City of Louisville on March 3, 1998 and vacated by Brinly-Hardy Company September 30, 1998.

The railroad building has become a strategic part of the Louisville Waterfront Development project as it has been converted to be the grand entrance, the “gateway” to the brand new Louisville Slugger baseball field. The railroad building has undergone a major renovation and now houses all of the ticket counters, many concession stands and eateries, gift shops, and also has several private suites available for rental to house larger groups. The Brinly-Hardy Company moved its operating facilities across the river to Jeffersonville, Indiana, about 5 miles from its old location in Louisville, Ky. This new manufacturing facility allows us to keep growing in important ways. Featuring state-of-the-art manufacturing technology, the new facility enhances our flexibility for accommodating large volume orders, as well as special order requests. The increased production and storage space allows us to better deliver rapid turnaround to all our valued customers. In addition, we have invested in new technology for our product development team, where innovation is an ongoing commitment.

The quality of Brinly products depends on the quality of Brinly people. We believe Brinly people are a special breed. They care about the company they work for, the products they make, and the service they give. While our growth has meant lots of new Brinly family members, over 20 percent of our people have been with us for more than 20 years. We must be doing something right. Maybe it’s the pleasure you get being part of a family and a family tradition, both of which are dedicated to an old-fashioned value: take pride in work well done.

What’s in a name? Well, just about everything. That’s why we believe products that carry the Brinly name, and reputation, have a lot to live up to. To prove it, we’re investing in the Brinly brand, in product innovation and improvement, in Brinly people, and Brinly customers.